Diaphragm pressure gauge

YP - 100 l seriesDiaphragm pressure gaugeSuitable for measuring the has certain corrosion resistance, the solidification or amorphous pressure or negative pressure of various kinds of fluid medium.Corrosion resistance depends on the diaphragm material.

The guide of the stainless steel corrosion pressure system and the shell are stainless steel, such as strong corrosion resistance.Mainly used in chemical, petroleum, textile industry, the measuring of tiny pressure gas, liquid is especially applicable to strong corrosive, viscous medium small pressure measurement (not solidification of crystals).

Seismic internal filling damping liquid and supporting device, has a good seismic performance.In the pressure of the measured medium has a strong impact or pressure pulse change and often sudden unloading occasion in the production process, and place of environmental vibration is larger, the seismic measure can be stable.

Corrosion resistance to shock and corrosion and seismic characteristics of two.

Second, the working principle:

YP - 100 l series of diaphragm pressure gauge is based on the elastic deformation of components (diaphragm) on the measurement system.Under the effect of pressure measured medium, the force - displacement corresponding elastic deformation of diaphragm, with the help of a connecting rod set of the transmission mechanism of the transmission and amplification by pointer fixed on the gear by measured values will be indicated on the dial out.

Applications:

YP - 100 l series diaphragm pressure gauge used to measure a certain corrosive. Viscous medium and noncrystalline or solidification of of all kinds of liquid medium pressure or negative pressure;According to the different requirements of measurement for corrosion resistance and choose different material of diaphragm;Instrument shell with stainless steel material;Can be used under the condition of the poor working conditions.

Four, the main features:

1, stable performance, high measurement precision, response speed faster.

2, measuring the total pressure, including gas and steam pressure.

3, the results of the measurement has nothing to do with the gas species, composition and properties.

4, in the process of the pressure, suction and deflated pressure gauge itself is very small, will not affect the measured pressure.

5, no high temperature parts, won't make the oil vapor.

6, if choose corrosion resistant materials, can measure the corrosive gas pressure.

7, firm structure, and sealing and makes the pipes easier to install.

8, easy operation, do not need to adjust, but need to check on a regular basis.

Five, the technical parameters:

1, instrument standards: Q / 320211 DGH07-2001;

2, instrument shell protection grade: IP64;

3, shock and corrosion resistance of the working environment resistance for the stipulated V.H. GB4439 level 4;

: 4, use, working temperature and corrosion - 40 ℃ ~ 70 ℃;

5, shock resistance, corrosion resistance: when pouring the liquid as glycerin - 5 ℃ ~ 55 ℃, pouring liquid for silicone oil - 25 ~ 55 ℃.

Six, regular maintenance/repair:

1, after a period of use, and pressure, pressure gauge movement deformation and wear, hard to avoid can appear some pressure gauge can produce all kinds of errors and failures.In order to guarantee the accuracy of its original without distortion, dissemination should be replaced in a timely manner, to ensure that the correct, safe and reliable.

2, pressure gauges need to clean them regularly.Because the interior of the pressure gauge is not clean, will increase the wear parts, thus affecting its normal work, serious can make the pressure gauge failure, scrap.

3, the pressure on the installation of pressure gauge, according to the regulations of JJG52-1999, its verification period is generally not more than half a year.

4 and pressure medium to large fluctuations, used frequently, the accuracy of the demand is higher, and more strict with safety factor, will test cycle shorten appropriately according to the specific situation.

Seven, use notice:

1, when using the environment temperature for - 40 ~ 70 ℃, relative humidity is not more than 80%, such as deviation from normal use temperature 20 ℃, the temperature must be included in the additional error.

2, must be installed vertically, and strive to maintain the same level with measuring points, such as the difference between high included in the additional error caused by the liquid column, but don't have to consider when measuring gas.When installation will watch case vent at the back of the jam, lest affect explosion-proof performance.

3, when using normal use of the measuring range: no more than 3/4 of the measurement limit under static pressure, under the volatility should not be more than two-thirds of the measurement limit.In the above two kinds of low pressure situation under large pressure gauge measuring zui should not less than a third of the lower limit, vacuum parts all use measurement of a vacuum.

4, such as when using vacuum gauge pressure failure or internal parts loose, should not work properly when fault repairs, maintenance or production manufacturer.

Eight, specifications and measurement range:

model | The name of the | Overall dimensions | Measuring range | Accuracy % |

YP-100L | FIG. 1 | 0-0.06;0-0.1;0-0.16;0-0.25;0-0.4; | + / - 2.5 | |

YP-100F | The flange | Figure 2 | ||

YP-100L-F | corrosion | FIG. 1 | ||

YP-100F-F | Flange connection corrosion | Figure 2 | ||

YP-100L-Z | seismic | FIG. 1 | ||

YP-100L-FZ | Seismic decay resistance | FIG. 1 | ||

YP-100L1-F | Corrosion diaphragm micro pressure table | FIG. 1 | 0-1.6;0-2.5;0 to 4;0 to 6;0 to 10;0 to 16;0 to 25;0 to 40;0-60; | |

YP-100F1-F | Flange connection corrosion diaphragm micro pressure table | FIG. 3 |

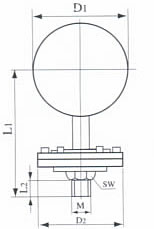

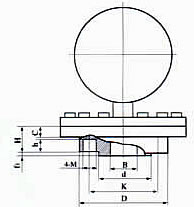

Nine, appearance size:

Table 1:

model | Overall dimensions mm | |||||

D1 | D2 | L1 | L2 | SW | M | |

YP-100L | 110 | 97.5 | 135 | 20 | 27 | 20X1.5 |

YP-100L-F | ||||||

YP-100L-Z | 165 | |||||

YP-100L-FZ | ||||||

YP-150L | 160 | 160 | ||||

YP-150L-F | ||||||

YP-150L-Z | 190 | |||||

YP-150L-FZ | ||||||

FIG. 1

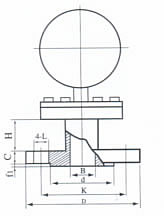

Table 2:

model | Measurement limitMPa | The pipe sizeDN | Flange connection | Screw holeL | ||||||

D | K | d | B | H | c | F1 | ||||

YP-100F | 0 ~0.1 | 32 | 140 | 100 | 78 | 31 | 50 | 16 | 2 | 18 |

40 | 150 | 110 | 88 | 38 | 50 | 16 | 3 | 18 | ||

50 | 165 | 125 | 102 | 49 | 50 | 18 | 3 | 18 | ||

0~2.5 | 32 | 140 | 100 | 78 | 31 | 50 | 18 | 2 | 18 | |

40 | 150 | 110 | 88 | 38 | 50 | 18 | 3 | 18 | ||

50 | 165 | 125 | 102 | 49 | 50 | 20 | 3 | 18 | ||

According to chemicalHG;National standardGBAnd JapanJIS;The United StatesANSISuch as standard. | ||||||||||

Figure 2 in figure 3

Table 3:

model | Measuring rangeKPa | The pipe sizeDN | Flange connection | Screw hole | |||||||

D | K | d | B | H | c | f1 | M | H | |||

YP-100F1-F | 0-1.6~0-60 | 20 | 90 | 65 | 50 | 26 | 28 | 10 | 2 | 10 | 14 |

25 | 100 | 75 | 60 | 33 | 28 | 10 | 2 | 10 | 14 | ||

32 | 120 | 90 | 70 | 39 | 28 | 10 | 2 | 12 | 14 | ||

40 | 130 | 100 | 80 | 46 | 28 | 10 | 3 | 12 | 14 | ||

Ten, selection list:

Ten, design selection and ordering information:

1, when ordering please indicate the type, name, measuring range, joint thread size, precision grade.

2, if you have special requirements, when ordering, please specify.

3, stainless steel diaphragm pressure gauges diaphragm material choice: in strong acid medium should choose HC HB TA diaphragm, best to four fluorine lining, the strong base class to use 316 l diaphragm.

After-sales service commitment:

1, our company sold by pressure gauge series product appeared quality problem within 12 months, responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.